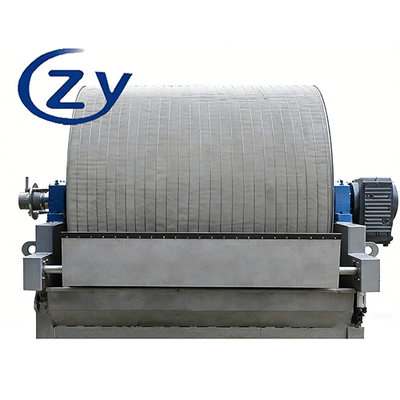

Filtre à vide Machine de déshydratation de l'amidon Extraction rapide de l'humidité Ultra-haute sécheresse Traitement industriel de l'amidon

Détails sur le produit:

| Lieu d'origine: | Chine |

| Nom de marque: | ZY |

| Certification: | ISO |

| Numéro de modèle: | VM10 |

Conditions de paiement et expédition:

| Quantité de commande min: | 1 ensemble |

|---|---|

| Détails d'emballage: | Emballage simple |

| Délai de livraison: | 20-30 JOURS |

| Conditions de paiement: | LC, T/T |

| Capacité d'approvisionnement: | 20set par mois |

|

Détail Infomation |

|||

| Nom du produit: | Filtre à vide | Brand name: | ZY |

|---|---|---|---|

| Matériel: | SS304 | Pouvoir: | 4KW |

| Capacité: | 2-8 t/h d'amidon sec | Tension: | 308v50hz |

| Composants de base: | Moteur, roulement, récipient sous pression | Garantie: | 1 an |

| Couleur: | Blanc argenté | Matériel de machine: | Acier inoxydable |

| Fonction des machines: | déshydratation de l'amidon | Qualité: | haut niveau |

| Portée des matériaux: | manioc, pomme de terre, patate douce | Industries applicables: | Usine de nourriture et de boissons |

| Mettre en évidence: | machine de déshydratation de l'amidon industriel,extraction de l'humidité de l'amidon de pomme de terre,transformation de l'amidon à haute sécheresse |

||

Description de produit

Cette machine de déshydratation d'amidon utilise la forte force d'aspiration générée par une pompe à vide pour créer un environnement de pression négative contrôlée à l'intérieur du tambour, permettant ainsi aux particules solides de la suspension d'amidon d'adhérer fermement à la surface du tissu filtrant du tambour. Le tambour tourne à une vitesse lente constante, favorisant la formation d'un gâteau d'amidon uniformément épais sur le milieu filtrant. L'humidité est efficacement éliminée et évacuée par le système de vide, tandis que le gâteau d'amidon séché est continuellement raclé par un mécanisme de raclage automatisé, assurant une déshydratation efficace et constante.

![]()

- Conception compacte et simplifiée avec une disposition opérationnelle intuitive qui réduit considérablement les coûts de maintenance à long terme

- Les composants résistants à l'usure de haute qualité améliorent la durabilité structurelle et prolongent considérablement la durée de vie de l'équipement

- Des dommages minimes aux matières premières pendant le nettoyage garantissent une qualité de produit constante et un débit stable

- Excellente compatibilité avec la production continue à grande échelle, combinée à une efficacité supérieure en matière d'économie d'eau, favorise des opérations durables

| Type | VF10 | VF15 | VF20 |

|---|---|---|---|

| Surface filtrante | 10m2 | 15m2 | 20m2 |

| Puissance | 5,5 kW | 11 kW | 18,5 kW |

| Capacité | 2 tonnes/h | 4 t/h | 5 t/h |

![]()

![]()